Lorem ispum

Mad About Molds

Watch our Movie Clip which shows you how Step-by-Step. (20 seconds)

SO ARE YOU READY? HERE WE GO!

Start by conditioning and rolling a ball of clay to fit your mold. Warm

up the clay by rolling it around in your hands and kneading it until it is

pliable and soft.

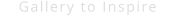

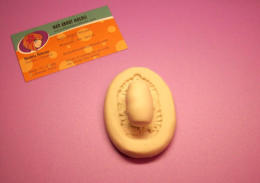

Here’s the casting that we

are demonstrating. Make

one yourself by following

our simple instructions.

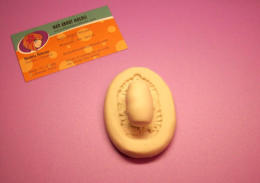

After conditioning your clay, dust the inside of the mold with

corn starch or baby powder using a fluffy artist brush or make-

up brush. Dip brush in powder, then tap off the excess. Lightly

dust mold cavity in a pouncing motion. Blow out excess powder

if needed to maintain detail.

Mold Release Powder is our favorite

mold release. It’s safe and completely

non-toxic. You can purchase it here.

Now place a ball of well

conditioned clay in the

center of the mold.

If you are using a shallow

mold you can place a sheet

of clay over the mold instead.

Next place a transparent sheet of plastic on the top of the ball of

clay. A clear page from a book report cover or one layer of a

page-protector works well. Or any other type of clear plastic

sheet that you have on hand that is sturdy, but not too sturdy

that it won't peal off the back of the clay later. Read on to see

why.

Clear Release Sheets are perfect for lifting your

mold casting from your molds. Once you

discover how to use these, you will wonder what

you ever did with out them. You can purchase

this item here.

Acrylic Square Tiles are helpful

for making mold castings with

perfectly flat backs, as shown in

the instruction video, and

mentioned in the step-by-step

instructions. Once you use it,

you will never mold without it.

You can purchase this item here.

Now place a clear glass or Plexiglas tile on top of the

clear release sheet.

Press the clear tile and release sheet down slowly filling in

the mold, allowing the excess clay to flow-over the edges.

You will be able to see what's going on underneath since

your tile is clear. Be sure to press down until you are happy

with the thickness of the back. Also, if you are concerned

about making the back perfectly level, glue four small Lego

pieces to each corner of the tile. This controls how far

down the tile will go, and keeps it level. You can add or

remove the Lego pieces to control the height of the tile and

the thickness of your casting.

Now remove the tile and set it aside. Lift a corner of the transparent paper carefully, so it pulls the

clay out with it. Remember that any over flow of clay can be cut off or sanded off after baking.

To remove your clay casting from the clear release sheet without distorting it, pop it in the freezer for

about 15 to 20 minutes. When you take it out it will be easy to peal the transparent paper off your

casting without distorting the clay. First I like to cut off the edges with a craft knife before removing the

release sheet so it does not slide around on your work surface when you cut it off. By keeping it on the

sheet you can turn and stabilize the casting while cutting off the excess clay. If you need to freeze it

again to peel off the sheet from the back it is well worth the extra effort and easy to do. I also like to

smooth out the clay edges with my finger or with a clay tool to reduce the need for sanding after the

piece is baked.

Before baking you might want to use a sharp

craft knife to remove any openings in your

casting. This is also the time to add any

cavities for stones or embellishments so that

you have a nice indentation to attach them into

after baking.

Remember to add the stones or accents after

baking or they may melt from the heat. I like to

make the cavities with a nail head since you can

get many sizes of nail heads for little or nothing.

If your object is going to be a charm or ornament,

insert a wire loop or eye screw before baking. Pin

backs, earring backs, and button backs can also

be used.

Use your

imagination and

have fun!

Click Next to go to our Advanced Instructions where you can

learn about different ways to use our molds and much more!

10 Steps for Using our Molds with Clay.

Our great technique will help you to make a perfectly flat backed mold

casting, without distorting it when removed from the mold.

Click here for instructions for using our Flexible Molds.

What are Clay Push Molds?

The term Clay Push Molds, refers to pressing softened clay or other casted material into a mold.

Dozens of highly detailed impressions can be made in minutes. Our simple process allows even novice

crafters to create pieces that look like they took hours to make. We hope this helps you make the most

of your molds and see how fun molding can be!

Basic Instructions

Lorem ispum

- Home

- About us

- Art clay projects pmc

- Basic instructions

- Cameos and molds

- Contact us

- Castings materials and instructions

- Casting recipes

- Chat

- Custom molds

- Creative ways to use molds

- Flexible mold instructions

- Gallery to inspire

- Payment and shipping

- Safety precautions

- Search and site map

- Testimonials

- Troubleshooting

- Video

Mad About Molds

Watch our Movie Clip which shows you how Step-

by-Step. (20 seconds)

SO ARE YOU READY? HERE WE GO!

Start by conditioning and rolling a ball of clay to fit your mold.

Warm up the clay by rolling it around in your hands and

kneading it until it is pliable and soft.

Here’s the casting that we

are demonstrating. Make

one yourself by following

our simple instructions.

After conditioning your

clay, dust the inside of

the mold with corn starch

or baby powder using a

fluffy artist brush or

make-up brush. Dip

brush in powder, then tap

off the excess. Lightly

dust mold cavity in a

pouncing motion. Blow

out excess powder if

needed to maintain

detail.

Now place a ball of well

conditioned clay in the

center of the mold.

If you are using a

shallow mold you can

place a sheet of clay

over the mold instead.

Next place a transparent

sheet of plastic on the top

of the ball of clay. A clear

page from a book report

cover or one layer of a

page-protector works well.

Or any other type of clear

plastic sheet that you have

on hand that is sturdy, but

not too sturdy that it won't

peal off the back of the clay

later. Read on to see why.

Now place a clear glass or

Plexiglas tile on top of the

clear release sheet.

Press the clear tile and release

sheet down slowly filling in the

mold, allowing the excess clay to

flow-over the edges. You will be

able to see what's going on

underneath since your tile is

clear. Be sure to press down until

you are happy with the thickness

of the back. Also, if you are

concerned about making the back perfectly level, glue four

small Lego pieces to each corner of the tile. This controls

how far down the tile will go, and keeps it level. You can add

or remove the Lego pieces to control the height of the tile and

the thickness of your casting.

Now remove the tile and set it aside. Lift a corner of the

transparent paper carefully, so it pulls the clay out with it.

Remember that any over flow of clay can be cut off or sanded off

after baking.

To remove your clay casting from the clear release sheet

without distorting it, pop it in the freezer for about 15 to 20

minutes. When you take it out it will be easy to peal the

transparent paper off your casting without distorting the clay.

First I like to cut off the edges with a craft knife before removing

the release sheet so it does not slide around on your work

surface when you cut it off. By keeping it on the sheet you can

turn and stabilize the casting while cutting off the excess clay. If

you need to freeze it again to peel off the sheet from the back it

is well worth the extra effort and easy to do. I also like to smooth

out the clay edges with my finger or with a clay tool to reduce

the need for sanding after the piece is baked.

Before baking you might want to use a sharp craft knife to

remove any openings in your casting. This is also the time to

add any cavities for stones or embellishments so that you have

a nice indentation to attach them into after baking.

Remember to add the stones or accents after baking or they may

melt from the heat. I like to make the cavities with a nail head

since you can get many sizes of nail heads for little or nothing.

If your object is going to be a charm or ornament, insert a wire

loop or eye screw before baking. Pin backs, earring backs, and

button backs can also be used.

Use your

imagination and

have fun!

Click Next to go to our Advanced Instructions where you can

learn about different ways to use our molds and much more!

10 Steps for Using our Molds with Clay.

Basic Instructions

Our great technique will help you to make a perfectly

flat backed mold casting, without distorting it when

removed from the mold.

Click here for instructions for using our Flexible Molds.

What are Clay Push Molds?

The term Clay Push Molds, refers to pressing softened clay

or other casted material into a mold. Dozens of highly

detailed impressions can be made in minutes. Our simple

process allows even novice crafters to create pieces that look

like they took hours to make. We hope this helps you make

the most of your molds and see how fun molding can be!